Line for the production of chewing gum performance 80-100 kg / h.

For preparation of chewing gum it is necessary to grind the sugar cleaned of impurities to the state of powdered sugar. This process takes place in a mill where the operator pours the sugar into the hopper. Warming the gum base occurs in a specialized furnace to a predetermined temperature. Loading and unloading is made manually. A polymer base and powdered sugar are placed manually in a special mixer, where the mass adding glucose syrup is warmed to 50- 60 ° C for 30 minutes. After mixing and dissolution of the basic ingredients, depending on the formulation, under the stringent proportions it should be added in the cooked mass the citric acid, flavors, glycerin, flavoring agents or other ingredients, continuing mixing to form a dough consistency. The received mass is discharged on the carriage and is allowed to cool for an hour. At this final stage, it is occurs the metabolism of the components and their mixing.

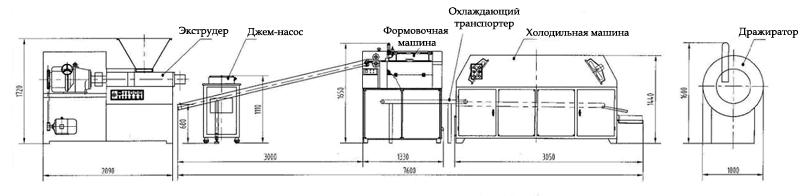

Then, the cooled mass is charged into the extruder, the ready fruit filling is fed from the jam pump on the die. At a very high pressure extruder extrudes a strand of future chewing gum into a molding machine, which it is given a different form of the future product.

Then, the formed chewing gums should be cooled immediately to prevent the product deformation. The chewing gum is loaded from the molding machine on the connected to it cooling conveyor, which transfers products in freezing machine. This is the moment, when the sugar, glucose and polymer base create the uniform quasi-polymer inside the sugar strand, which is used to be called the chewing gum.

At the exit of the cooling machine it is installed the portable containers in which the product is loaded. In order to give the chewing gum the final form and taste it is transferred manually into the machines for polishing and colored coating of the chewing gums (grinder), where ingredients are input in the strict proportions. Mixing is carried out until the uniform color is achieved. Then, the chewing gum is loaded into container and allowed to stay for a while for the final solidifying.

The final stage of production is packing. The chewing gun is manually feed from the portable containers into the hopper of automated packing machine. The ready for selling product comes from it.

Equipment

1. Furnace for the gum base. It is made of ordinary steel and insulating material. Heating elements are controlled by heating controller.

Technical parameters:

Capacity: 60 kg

Power: 9 kW

Weight: 390 kg

Size: 1500 x 1000 x 2160 mm

2. Sugar mill.

It is used for the preparation of powdered sugar. The granule size

can be achieved by changing the sieve.

Main parameter:

Rotational speed of the shaft (rev / min) 4200

Capacity (kg / h): 50-250

Engine power (kW): 5.5

Fineness: 0-140

Dimensions: 880 x 520 x 1360mm

Weight (kg): 150

3. Chewing gum base mixer.

The latest design is based on advanced technology.

It is widely used in the pharmaceutical, chemical, food and other industries.

Technical parameters:

Volume (liters): 100

Engine power (kW): 2.2

Dimensions: 1100 x 440 x 900 mm

Weight: 2,580 kg

4. Extruder.

It is used for extruding a chewing gum mass.

Basic parameters:

Transmission power: 5.5kw

Water heating power of 2 * 6 kW

Total power: 20 kW (approximately)

Power supply: 380V, 50HZ

Water temperature: <30

Water Pressure: 1.5-2kg / cm ²

Water consumption: 200L / h

Weight: 1400kg

Dimensions: 2530X1040X1840mm

5. Filling center. Jam pump.

Technical parameters:

Power: 380V, 50Hz

Main engine: 0.55kW

Engine blade 0.37kVt

Heating power: 6 kW

Total power: 7 kW (approx.)

Water consumption 100 l / h

Water temperature: <30

Water pressure: 1.5-2kg / cm ²

Maximum capacity: 150 kg / h (approx)

Weight: 390kg (approx.)

Dimensions: 1560 mm * 840 mm * 1210mm

6. Molding machine

It is used for the production of circular / oval gum. The machine makes "ropes" of the mass coming from the extruder, cuts it into the desired size and form in accordance with a predetermined configuration.

Technical parameters:

Speed (the number of cuttings): 28 cycles / min

Power: 1.5 kW

Dimensions: 1330 x 550 x 1620mm

Weight: 800kg

7. Cooling conveyor.

Hands down, partially the product from the cooling machine to the molding machine

Specifications:

Engine power: 380 1.1kw

Size: 2500 x 100 x 1000-1600

Specifications:

Engine power: 380 1.1kw

Size: 2500 x 100 x 1000-1600

8. Freezing machine.

Is designed for cooling the formed product. Since the machine is equipped with a sieve system, thus the product protection from any deformation is occurred during cooling.

Specifications:

Operating speed: 68 cycles / min.

Engine power: 380 1.1kw

Fan Power: 220 4x130kw

Size: 3050x1420 x1440mm

Number of fans: 4, 16 inches

9. Machine for polishing and colored coatings of the gum

Diameter of the polishing pot: 1000mm

Motor power: 2.2 kW

The blower power: 0.37 kW

Heating Power: 2.5 kW

External size: 1500 x 1100 x 1700 mm

3 pcs.